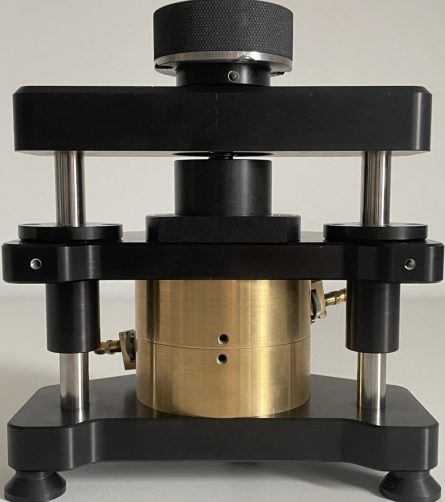

Q-choke Split Cylinder Resonator (Q-SCR)

for precise measurements of thin & thick materials

- Q-choke SCR*

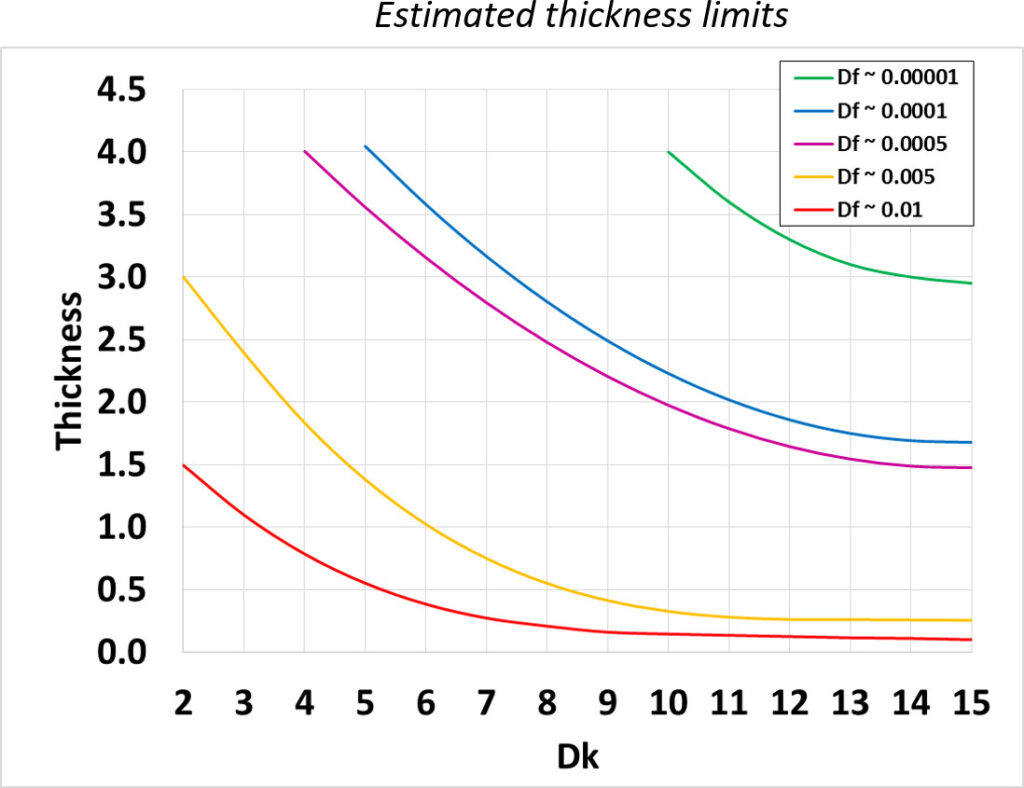

- Overcoming sample thickness limitations of known solutions

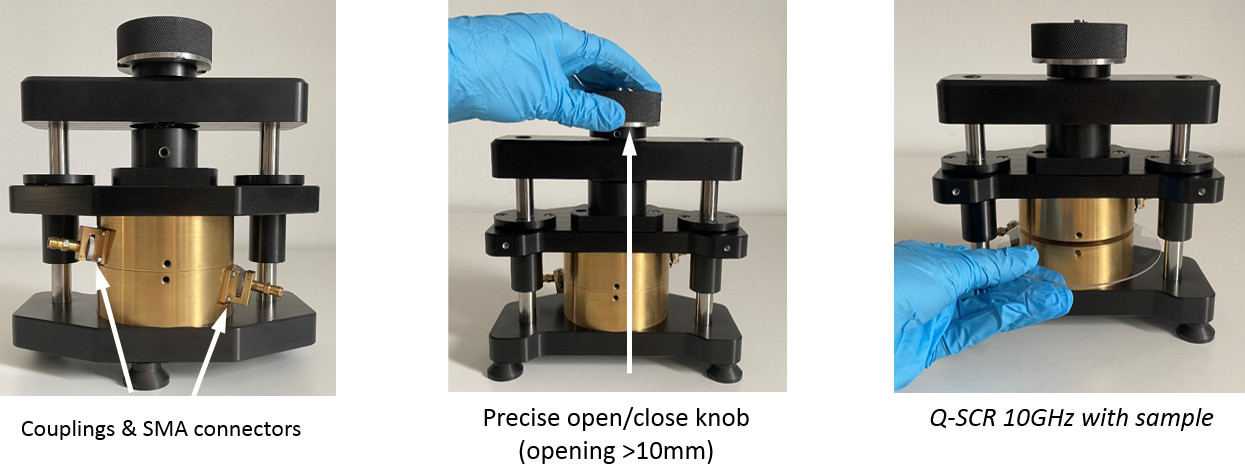

- Applicable to thin & thick materials (e.g. thin foils, bumper plaques, vacuum windows, 3D printed materials, etc.)

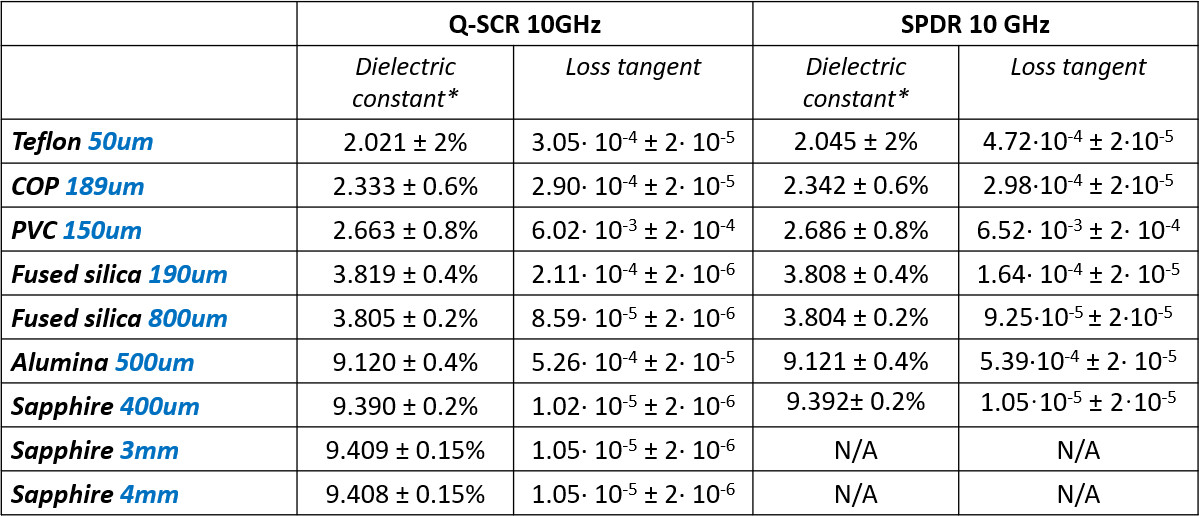

- Q-SCR 10GHz operation parameters:

- Overcoming sample thickness limitations of known solutions

- Dk = 1 - 15

- Df > 10-6

- accuracy:

-

δDk < 0.2%

δDf < 2% - high repeatability:

-

for COP 187µm, Dk=3.347,

→ st. dev.=0.0002 - sample dimensions

-

min 40 x 40 mm

max 100 x 100 mm - thickness:

- Up to 4 mm for low-loss materials (e.g. sapphire)

- Q-SCR 10GHz measurement procedure

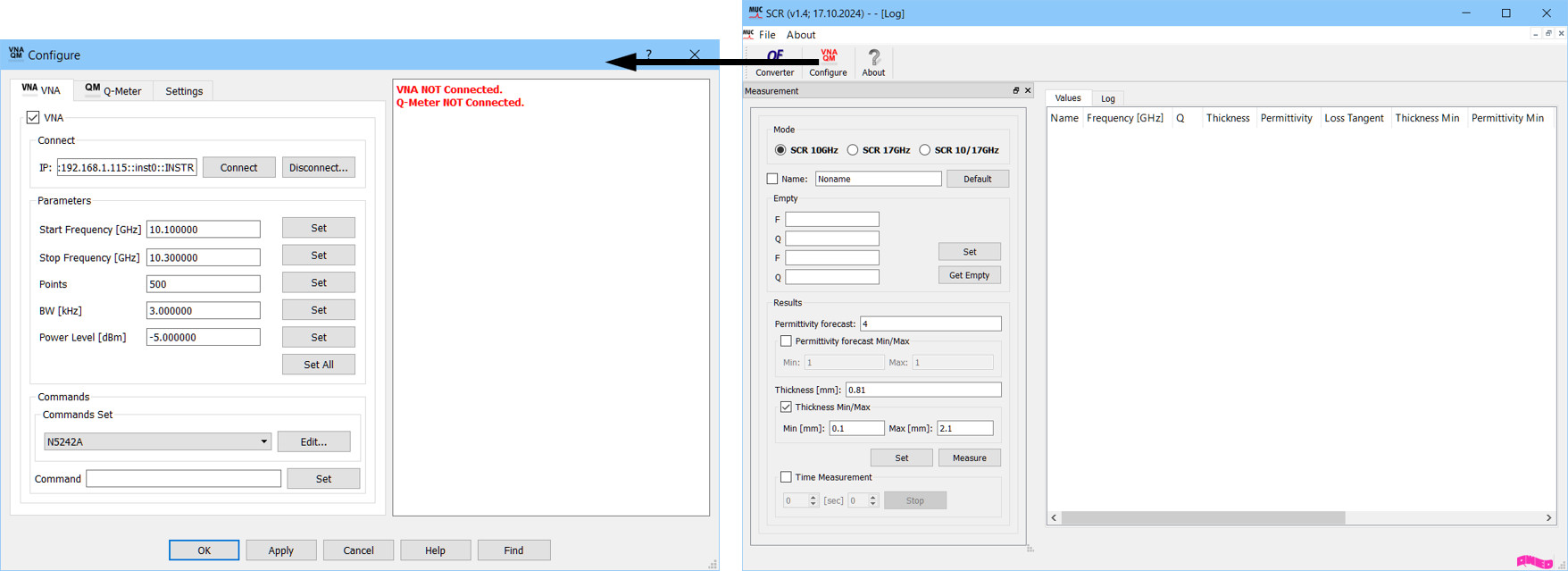

- Equipped with dedicated software:

- automating and controlling the measurement

- extracting the dielectric constant (Dk) and dissipation factor (Df) of the material under test

- Two-step measurement procedure:

- resonant frequency and quality factor measured for an empty closed Q-SCR device

- resonant frequency and quality factor measured for a sample-loaded Q-SCR

- measured frequency shift and quality factor change are used to extract Dk and Df

*uncertainty of Dk extraction is due to sample thickness variation

*M. Celuch, M. Olszewska-Placha, L. Nowicki and W. Gwarek, „A Novel Q-Choked Resonator for Microwave Material Measurements Alleviating Sample Thickness Limitations of Existing Techniques,” in IEEE Microwave and Wireless Technology Letters, vol. 34, no. 6, pp. 845-848, June 2024